Magsafe magnets' customized solution

Magsafe magnet array transmitter end

Magsafe magnet receiving end

Magsafe magnet ring with sticker

Wireles charging magnets & Magsafe Magnets Applications

Parameters of magsafe magnets wireless charging transmitter:

Size: φ54 -φ46 (36 pcs + 2 pcs)

Material: NdFeB N52SH

Suction force: 1.0KG – 10KG

Main Magnetic Circuit Distribution:Plane two outer N – inner S

Positioning Magnetic Circuit Distribution: Planar Triple Pole N-S-N

Number of magnets: 36 main body magnets + 2 positioning magnets

Magnetic flux: more than 3500GS

Parts : Tile magnet + square magnet + iron sheet + glue

Surface treatment :Nickel-Zinc

Salt spray requirement : Neutral salt spray 8H-72H (optional)

Packing requirement: PE bag + carton

Environmental requirements: ROSH, REACH

magsafe magnets wireless charging receiver end parameters:

Size: φ54 -φ46 (36pcs+2pcs)

Material: NdFeB N52SH

Suction force:1.0KG – 6KG

Main Magnetic Circuit Distribution:Plane secondary Outer S-Inner N

Positioning Magnetic Circuit Distribution: Planar Triple Pole S-N-S

Number of magnets: 36 main body magnets + 2 positioning magnets

Magnetic flux: more than 3500GS

Parts : Tile magnet + square magnet + Mylar + double-sided tape

Surface treatment :Nickel-Zinc

Salt spray requirement : Neutral salt spray 8H-72H (optional)

Packing requirement: PE bag + carton

Environmental requirements: ROSH, REACH

Magsafe Metal Ring parameters:

Material: Neodymium/ Steel or available customized

Color: Any

Compatibility All Self-Phone

Size: 5*45*1.2mm / Without Magnet: 55*45*0.9mm

Why trusted us

Compatibility:

Works seamlessly with all MagSafe-enabled smartphone devices and accessories.

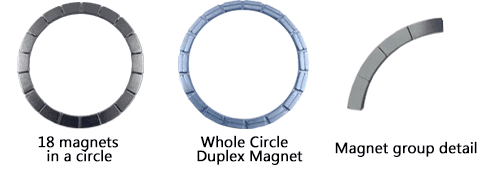

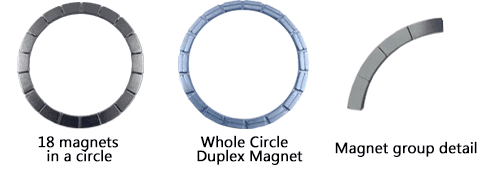

Automatic assembly

All of our magsafe magnetic assemblies are manufactured using automated equipment to improve product quality and reduce manufacturing costs for our customers while maintaining product stability and consistency.

First MFG in China to develop wireless charging magnet assemblies:

Far more experiences in developing various multi-application scenarios for Magsafe magnets, due to we are China’s first develping both wireless charging module transmitter and receiver module manufacturer at the same time.

About US

Company Profile: TL Magnets CO., LTD – The Leader of Wireless Charging Magnetic assemblies Solution

TL Magnets CO., LTD is an innovative company focusing on wireless charging Magnetic assemblies solutions, dedicated to solving the core needs and pain points of wireless charging magnetic assemblies’ buyers and providing efficient, safe and compatible wireless charging solutions. We understand that convenience and efficiency are the key factors consumers use to choose wireless charging products in the fast-paced modern life. Therefore, we continue to push for technological innovation to meet and exceed market expectations.

We are cooperating with as below:

vehicle accessories manufacturers,

smartphone makers,

tablet makers,

laptop makers,

powerbank manufacturers,

other consumer electronic device manufacturers,

cell phone accessories manfacturers,

smart home device manufacturer,

system integrators,

OEMs, R&D organizations and other B2B solution providers

Our Core Values:

1. Innovative Technology: TL Magnets CO., LTD utilizes cutting-edge wireless charging technology to provide wireless flash charging solutions up to 40W, ensuring charging speeds comparable to wired charging, and even better in some cases.

2. Comprehensive compatibility: Our products support Qi and other mainstream wireless charging standards, to ensure compatibility with the vast majority of smart devices on the market, eliminating users’ concerns about device compatibility.

3. Safety: Safety is the primary consideration in our design. Our wireless charging magnetic assemblies are equipped with advanced overheating protection and foreign object detection systems to ensure safe and stable operation in various environments.

4. Cost-effectiveness: By optimizing our design and production processes, we provide cost-effective wireless charging magnetic assembly solutions designed to reduce users’ long-term operating costs without sacrificing performance and quality.

5. Technical standardization: We actively participate in the development and promotion of industry standards, and are committed to reducing technical differences in the marketplace and providing users with a seamless one-stop solution for charging modules.

At TL Magnets CO., LTD, we are committed to being the leader in the wireless charging magnets & Magsafe magnets’ field, solving buyers’ pain points and meeting their needs by providing innovative, efficient and safe products and services. We believe that through our efforts, we can promote the development of wireless charging magnetic assemblies.

TL Magnets CO., LTD – Your trusted wireless charging magnets‘ assemblies solution provider.

TL wireless charging Magnets in Numbers

Material production

Material production base factory area of 8000 square meters, personnel 100 people

R&D and processing

Product research and development, processing and assembly plant, electroplating plant, 120 people

15+

TL Magnets has National patents

750+

Happy Clients

ISO9001+14001

passed ISO9001 quality system, IS014001:2004 environmental management system

Annual production capacity

Annual production capacity of 1,000 tons of sintered NdFeB permanent magnet materials

Magsafe magnet array Project R&D Principle

Trusted strong magnets’ products come from R&D and process control

TL Magnets Magsafe magnetic assemblies advantage

1: Fully automated assembly equipment-cost advantage

TL magnet industry from 2020 to start the receiving end, the transmitting end of the program, is also the industry’s earliest group of contact program manufacturers, after 3 years, Tongli magnetic industry continue to optimize the production of automation equipment, from the multi-wire cutting, fully automated patch, fully automated magnetization, invested a lot of R & D efforts, in order to ensure that the suction force and temperature resistance to the case of the production efficiency to the limit, so as to achieve the industry’s most cost advantage! The most cost-effective manufacturer in the industry

2:Multi-specification selection – delivery guarantee

TL Magnet industry for customers to solve the problem of providing solutions, and all the solutions to organize and validate the formation of independent standard products, to facilitate rapid selection of customers, standard product series can be achieved within 3 days delivery, custom products can be delivered in 9 days delivery guarantee

3: Patent certificate – for customers to protect their rights

Considering the intellectual property rights of the market and the interests of customers, Tongli Magnetic Industry started to apply for utility model patents to the receiving end and the transmitting end in 2021, and now we have obtained 5 patents to protect the intellectual property rights of customers.

4:Product standardization – quality stability

TL Magnets has formed standardized operations for the products of receiving end and transmitting end from raw materials, slicing, processing, plating, assembling, and through systematic quality control and CPK control of product dimensions, we carry out 100% full inspection after the finished products are completed to achieve the quality level of zero defects, and we can achieve the defective control of less than 100 PPM, which is worthy of customer’s trust.

5: Accurate positioning – charging efficiency multiplier

The biggest problem of wireless charging is the coil and coil speed transmission efficacy, Tongli Magnetic Industry utilizes the magnetic group N-S-N plane three pole arrangement, independent research and development of magnetizing equipment, so that the product can ensure a clear magnetic circuit, magnetic pole distribution uniformity, magnetic flux saturation quality requirements, and ultimately achieve the effect of doubling the charging efficiency.

TL Magsafe Magnets' Quality Assurance System

Quality is our cultures, Customers’ money in safe our businesses in safe, without quality without future.

Powdering (air flow milling)

Control points: 1: Operation standard management 2: Material testing 3: IPQC exception management

Hydrogen break

Control points: 1: Material Testing . 2:Operation standard management 3: IPQC exception management

Melting

Control points: 1:Composition ratio management 2:Melting parameter control 3: IPQC abnormality management

Raw material preparation

Control points: 1: Incoming material inspection control 2: Material composition inspection 3: Selection of metal dealers

Molding

Control points: 1:Magnetization direction control 2: Blank size control 3:IPQC abnormality management

Sintering

Control points: 1:Operation standard management 2: IPQC abnormality management 3:Equipment operating parameters

Statute of limitations

Control points: 1: Timing standard operation 2: Timing parameter table management 3: Equipment parameter management

Rough material testing

Control points: 1: Performance parameter inspection 2:Storage environment management 3: Warehouse management mixing control

Slicer processing

Control points: 1: IPQC inspection 2:Size focus control 3:Equipment parameter spot check

Alien shape processing

Control points: 1: IPQC inspection 2:Size key control 3:Equipment parameter spot check

Surface Plating

Control points: 1: Plating IQC inspection 2: Plating performance test 3: Plating environmental protection test

Assembly/Magnetization

Control points: 1: IPQC inspection 2:Performance test delivery inspection 3: Management of key processes

Talk to us

Have any questions? We are always open to talk about your business, new projects, creative opportunities and how we can help you.

MagSafe Magnets assemblies surface treatment

Magsafe magnets are available in the following surface treatments:

1.Electroplating:

Through electrochemical deposition technology to form a layer of metal plating on the surface of the magnet, common plating materials are nickel ,Zinc , gold and copper, which can improve the corrosion resistance and abrasion resistance of the magnet.

2. Surface drawing process:

through mechanical processing methods to form a texture on the surface of the magnet, to improve the appearance of texture and wear resistance.

3. Sand blasting and powder spraying:

Use sand blasting technology to remove impurities and oxidized layer on the magnet surface, while powder spraying forms a protective film on the surface, which enhances the wear resistance and corrosion resistance.

4. Polishing:

Make the magnet surface smooth by mechanical or chemical methods to improve the quality of appearance.

5. Coating:

Coating a layer of protective film on the magnet surface, which can be paint, UV varnish or other types of coatings to enhance wear resistance, corrosion resistance or improve the appearance.

6. Bite:

Form patterns or textures on the magnet surface to improve feel and appearance.

7. Pre-treatment:

Activate and sensitize the magnet surface before plating to remove surface oxides and improve surface activity.

8. Post-treatment:

After plating is completed, drying, polishing and sealing are carried out to remove residual moisture and oxides and to improve the corrosion resistance of the coating.

9. Laminating:

Including hot stamping, IMD (In-Mold Decoration), OMD (Out-Mold Decoration), etc., a decorative or protective film layer is formed on the surface of the magnet through laminating technology.

10. Laser engraving:

Marking, cutting or internal engraving on the surface of magnets through laser engraving technology to achieve specific decorative effects or functional requirements.

Customer Reviews